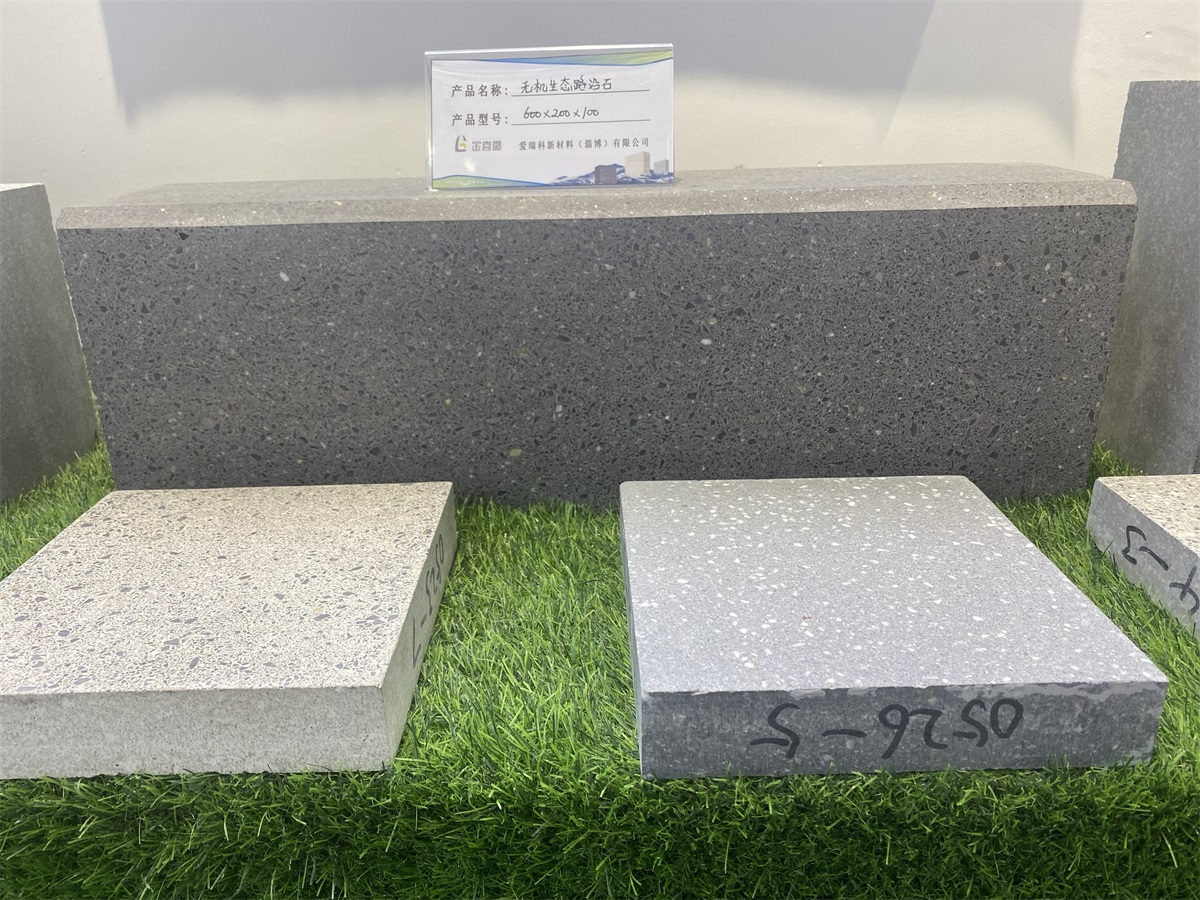

混凝土透水磚生產值得關注的幾個問題

透水鋪裝,特別是透水磚發揮著越來越大的作用,而從目前透水磚應用效果來看,還存在著很多問題,亟待解決,比如:

Permeable paving, especially permeable bricks, is playing an increasingly important role. However, from the current application effect of permeable bricks, there are still many problems that need to be solved urgently, such as:

目前山東透水磚在使用中,經受長時間風吹雨打、車輛碾壓,容易出現質量問題;磚體內部縫隙多,所以抗壓、抗彎強度低、耐磨強度低;比較容易損壞,損壞后需要相關部門重新進行修理維護,可能會導致相關部門工作壓力大;現在還沒有相對成熟的技術來清除透水磚縫隙中堆積的灰塵、雜質和其他沉積物。特別在北方地區冬季室外溫度較低,雨雪滲入透水的孔隙后會產生反復凍融循環,導致凍脹破壞,加上透水磚密度及抗壓強度比普通硬化路面地磚低,其凍脹破壞會更嚴重。

At present, permeable bricks in Shandong are prone to quality problems due to prolonged exposure to wind, rain, and rolling by vehicles; There are many internal gaps in the brick body, resulting in low compressive and flexural strength, as well as low wear resistance; It is relatively easy to be damaged and needs to be repaired and maintained by relevant departments after damage, which may lead to high work pressure on relevant departments; There is currently no relatively mature technology to remove dust, impurities, and other deposits accumulated in the cracks of permeable bricks. Especially in the northern regions, the outdoor temperature is relatively low in winter, and repeated freeze-thaw cycles occur when rain and snow penetrate permeable pores, leading to frost heave damage. In addition, the density and compressive strength of permeable bricks are lower than those of ordinary hardened road tiles, and their frost heave damage will be more severe.

透水磚不用于結構部位,不涉及安全問題,普遍沒有引起足夠的重視,考察中發現很多值得關注的問題,這些問題具有普遍性。

Permeable bricks are not used in structural parts and do not involve safety issues. They have generally not received sufficient attention, and many noteworthy issues have been found during the inspection, which are universal.

對于原材料的質量控制。透水磚對原材料要求比較苛刻,特別對于骨料的粒徑、粒型、含泥量、含粉量、母材強度等,進場的原材料要實時把控質量,這就對檢測人員的技術水平和試驗室相關儀器設備的配置提出了要求。

For quality control of raw materials. Permeable bricks have strict requirements for raw materials, especially for the particle size, shape, mud content, powder content, and base material strength of aggregates. The quality of raw materials entering the site must be controlled in real time, which requires the technical level of testing personnel and the configuration of relevant instruments and equipment in the laboratory.

考察中發現,試驗室人員和儀器設備配置普遍不足,有的就沒有試驗室,也沒有相關技術人員,還停留在小作坊階段,質量控制何從談起?有的試驗室連基本的石料篩分都不能做,買來什么用什么,恒溫恒濕養護箱也沒有,更別提標養室。混凝土的強度如何評價?

During the inspection, it was found that the personnel and equipment configuration in the laboratory were generally insufficient. Some did not have a laboratory, nor did they have relevant technical personnel, and were still in the stage of small workshops. How could quality control start? Some laboratories cannot even perform basic stone screening, use whatever you buy, and do not have a constant temperature and humidity curing box, let alone a standard curing room. How to evaluate the strength of concrete?

原材料的儲存要在封閉料倉里,以保證含水量的穩定以及不受環境中風沙塵土的影響。隨著環保意識的增強,現在多數企業都封閉了料倉,但仍有個別企業露天堆放。

The storage of raw materials should be in closed silos to ensure stable moisture content and protection from the impact of environmental wind, sand, and dust. With the increasing awareness of environmental protection, most enterprises have closed their silos, but there are still some enterprises that stack them outdoors.

配料攪拌成干硬性混凝土后開始生產,制磚機振動壓制成型磚后,緊接著是養護!這一環節多是利用自身的水化熱蓄熱養護,低溫季節溫度不夠時會通熱蒸汽進行加溫加濕。養護窯更有利于磚的早期養護,溫度濕度控制更精準,對空間的利用也更合理!

After mixing the ingredients into dry and hard concrete, production begins, and the brick machine vibrates and presses the formed bricks, followed by curing! This process mostly utilizes its own hydration heat storage for maintenance. When the temperature is not enough in the low temperature season, hot steam will be used for heating and humidification. The curing kiln is more conducive to the early maintenance of bricks, with more precise temperature and humidity control, and more reasonable utilization of space!

混凝土透水磚多用于廣場或人行道路,不涉及結構安全,各生產單位普遍重視程度不夠,此次考察中,有幾點感受深刻:

Concrete permeable bricks are mostly used in squares or pedestrian roads, and do not involve structural safety. Generally, production units do not attach enough importance to them. During this inspection, there are several profound feelings:

(1)對試驗室設備和人員的配置水平需要提高,因為這是保障材料從進場到產品出廠的技術保障。

(1) The level of equipment and personnel allocation in the laboratory needs to be improved, as it is a technical guarantee to ensure that materials are delivered from the site to the factory.

(2)原材料的儲存很關鍵,隨著國家對環保的重視,現在多數企業封閉了料倉,有的建設了筒倉,封閉料倉可以保證含水量的穩定,減少環境中風沙塵土的影響,但也有部分企業受場地小、儲量大的限制,存在部分、甚至全部露天堆放的情況。

(2) The storage of raw materials is crucial. With the country's emphasis on environmental protection, most enterprises have closed their silos, some have built silos, which can ensure stable water content and reduce the impact of wind, sand and dust on the environment. However, some enterprises are limited by small sites and large reserves, and some or even all of them are stored outdoors.

(3)對出養護窯(養護棚)后的養護重視程度普遍不夠,透水磚屬于水泥制品,出窯后養護不足、缺水導致水泥水化不充分,表層容易起粉、抗磨性下降、容易被凍壞,加強后期養護措施至關重要。更多相關的內容就來我們網站http://www.cpw944.cn咨詢!

(3) The level of attention paid to the maintenance after leaving the curing kiln (curing shed) is generally insufficient. Permeable bricks belong to cement products, and insufficient maintenance and water shortage after leaving the kiln lead to insufficient hydration of the cement. The surface layer is prone to powdering, decreased wear resistance, and is prone to freezing. Strengthening later maintenance measures is crucial. For more relevant content, come to our website http://www.cpw944.cn consulting service

上一篇:路沿石直線型、曲線型價格計算方法

下一篇:植草磚為什么會受到市場青睞呢?

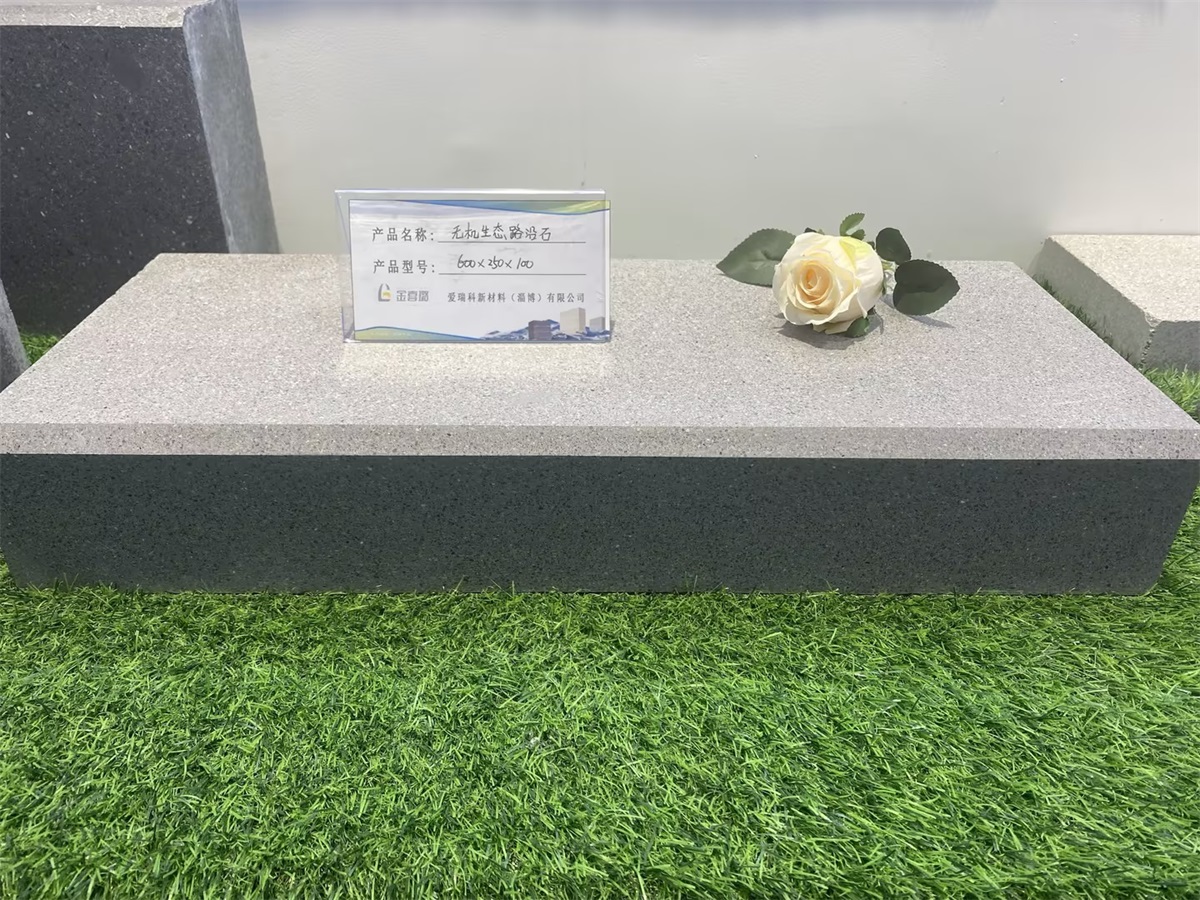

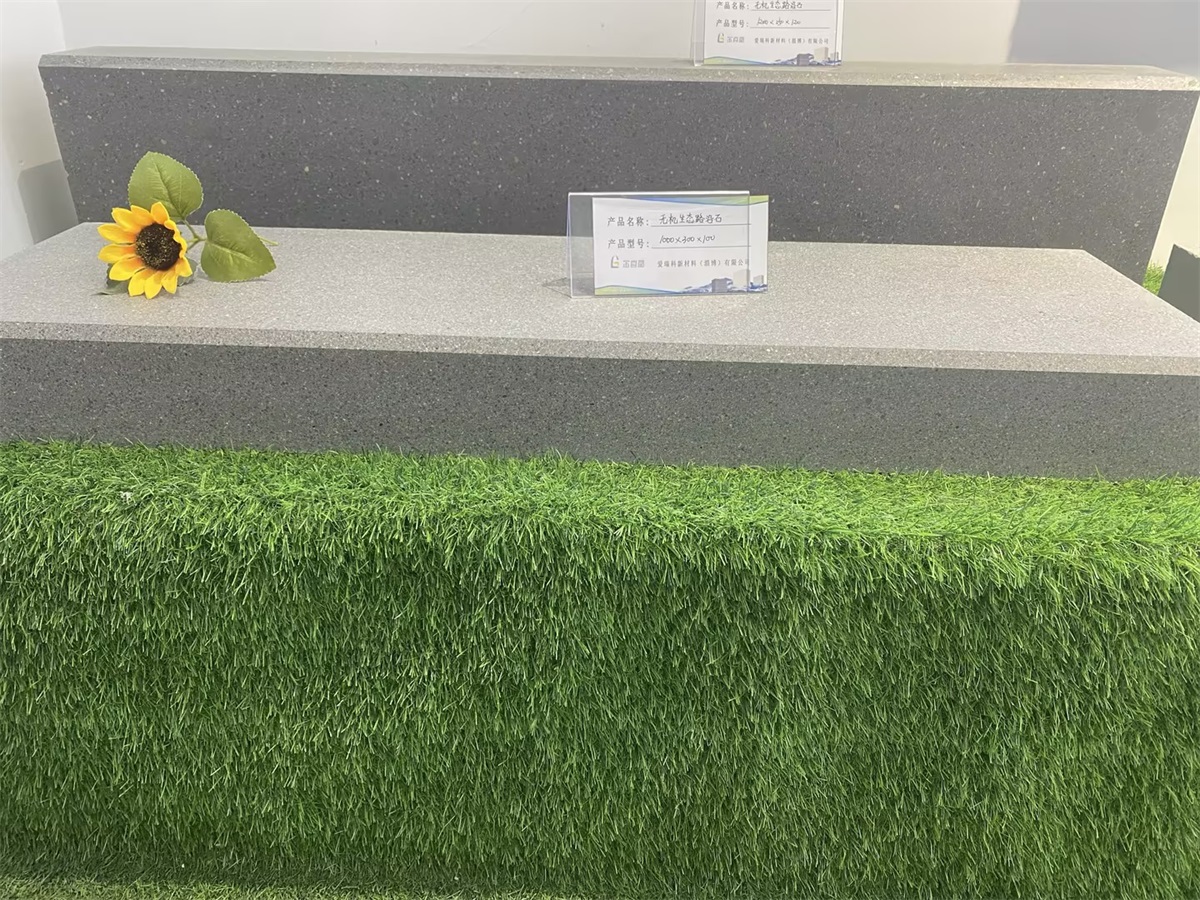

相關產品

相關新聞